+91 9953 65 9594

Maintenance Tips for Structures Using Rebar Couplers

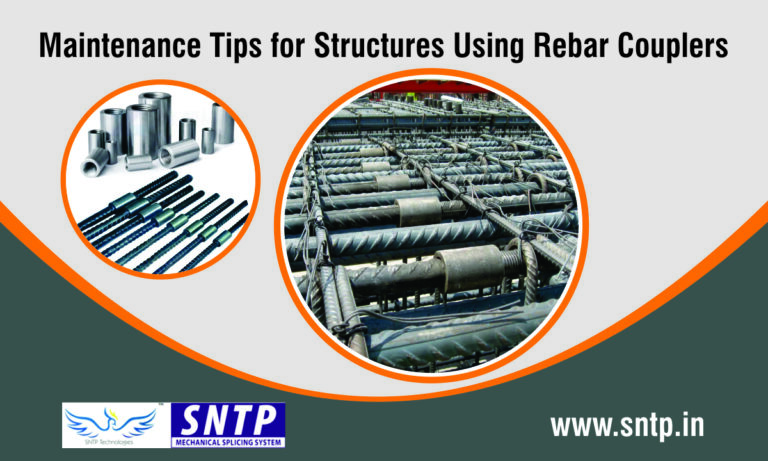

In modern construction,Rebar couplers have become a game-changer, offering stronger, more efficient, and cost-effective reinforcement solutions compared to traditional rebar lapping. These mechanical connectors join steel bars end-to-end, ensuring a continuous load transfer while maintaining structural integrity. While rebar couplers enhance durability and reliability, regular maintenance of structures using these connectors is essential to maximize their lifespan and performance. This article provides detailed tips and best practices to maintain structures reinforced with rebar couplers.

Understanding Rebar Couplers

Before diving into maintenance strategies, it’s crucial to understand how rebar couplers work. Rebar couplers are designed to connect two steel reinforcement bars mechanically. Unlike overlapping bars, couplers provide a direct load path, reduce material wastage, and accelerate construction timelines. Their design ensures that stress is evenly distributed along the bars, minimizing weak points and enhancing the overall strength of the structure.

Types of Rebar Couplers:

- Threaded Couplers: Bars are screwed together using pre-threaded ends.

- Swivel/Mechanical Couplers: Allow flexibility in bar alignment.

- Grouted Couplers: Filled with high-strength grout for added bonding.

Each type requires slightly different maintenance practices, but general care principles remain consistent.

Why Maintenance Is Important

Even though rebar couplers are designed for longevity, environmental factors, heavy load stress, and construction wear can impact performance over time. Neglecting maintenance can lead to:

- Corrosion of steel bars

- Reduced load-bearing capacity

- Structural cracks or failures

- Increased repair costs

Proper maintenance ensures structural safety, prolongs service life, and maintains the integrity of critical infrastructure such as bridges, metro systems, tunnels, and high-rise buildings.

1. Regular Visual Inspections

The first step in maintaining structures with rebar couplers is routine visual inspections. Key points to monitor include:

- Surface Corrosion: Check for rust or discoloration around couplers.

- Alignment Issues: Ensure bars connected via couplers remain straight and properly aligned.

- Cracks or Gaps: Look for concrete cracks exposing the couplers, which may indicate stress or improper installation.

Visual inspections should be conducted at least twice a year, or more frequently for structures exposed to harsh weather, chemicals, or high load stress.

2. Protect Against Corrosion

Steel corrosion is a primary concern for all reinforced structures. Although rebar couplers are manufactured using high-strength steel or corrosion-resistant alloys, additional preventive measures are necessary:

- Use Anti-Corrosion Coatings: Apply epoxy or zinc coatings on exposed couplers.

- Waterproof Concrete Cover: Ensure concrete encases the coupler sufficiently to prevent moisture penetration.

- Avoid Chloride Exposure: In coastal or chemical-exposed areas, minimize contact with saltwater or de-icing salts.

Maintaining a dry, well-sealed environment around couplers significantly reduces the risk of rust and structural damage.

3. Periodic Structural Testing

Alongside visual inspections, periodic structural testing is critical to ensure the couplers and connected rebars maintain optimal performance. Common testing methods include:

- Ultrasonic Testing: Detects internal defects or cracks in couplers.

- Load Testing: Verifies the structure’s capacity to handle expected stress.

- Non-Destructive Testing (NDT): Examines couplers without damaging the structure.

Testing should follow the manufacturer’s guidelines and regulatory standards, particularly for infrastructure projects with heavy loads.

4. Address Minor Issues Immediately

Small problems can escalate quickly if ignored. During inspections, if any of the following are detected, take immediate action:

- Loose Couplers: Tighten threaded couplers or consult engineers for mechanical adjustments.

- Concrete Spalling: Repair damaged concrete around couplers to prevent exposure.

- Signs of Stress or Bending: Evaluate structural load distribution and reinforce if necessary.

Prompt maintenance prevents minor defects from becoming major structural failures.

5. Proper Cleaning Practices

Debris, dust, or chemical residues can accelerate deterioration. Follow these cleaning tips:

- Remove Debris: Clear dust, dirt, and construction debris around exposed couplers.

- Avoid Harsh Chemicals: Use mild cleaning agents; avoid acids or highly corrosive substances.

- Inspect After Cleaning: After cleaning, recheck couplers for cracks, misalignment, or rust.

Regular cleaning ensures couplers remain functional and extends the structure’s durability.

6. Maintain Documentation and Records

Keeping detailed maintenance records is a best practice for long-term structural management. Records should include:

- Date and results of visual inspections

- Maintenance actions performed

- Structural testing outcomes

- Notes on any repairs or replacements

This documentation not only helps in proactive maintenance but also ensures compliance with safety regulations and BIS standards.

7. Use Professional Inspection Services

For large-scale projects or critical structures, it is advisable to hire certified structural engineers or specialized maintenance teams. They can:

- Conduct advanced diagnostic testing

- Identify hidden structural weaknesses

- Recommend preventive measures tailored to specific coupler types

Professional maintenance ensures compliance with safety standards and maximizes the lifespan of the structure.

Conclusion

Rebar couplers have transformed the construction industry, offering a reliable, efficient, and modern alternative to traditional rebar connections. However, the longevity and performance of structures using couplers depend heavily on proactive maintenance practices. By conducting regular inspections, protecting against corrosion, performing structural testing, addressing issues promptly, cleaning effectively, maintaining detailed records, and using professional services, engineers and builders can ensure their structures remain safe, strong, and durable for decades.

With proper care, SNTP Technologies’ BIS-certified rebar couplers not only provide superior structural strength but also deliver peace of mind, allowing India’s infrastructure to grow safely and sustainably.

© Copyright 2017.SNTP All Rights Reserved.

Design & Developed By Star Web Maker