Other products and Accessories

Calibrated Torque Wrench & Pipe Wrench

.jpg)

SNTP TorquePro – Torque Wrench

Precision in Every Turn

The SNTP TorquePro - Torque Wrench is engineered for high-accuracy torque application in structural and mechanical assemblies. Designed for durability and consistency, TorquePro ensures that critical fastenings of each and every SNTP Coupler meet exact torque requirements — reducing risk of over-tightening or failure.

Key Benefits:

-

High-accuracy torque calibration

-

Robust, ergonomic design for operator comfort

-

Easy torque setting and clear visibility

-

Suitable for industrial, construction, and rebar coupler applications

-

One universal size suitable for dia 12mm-50mm

SNTP IronJaw – Pipe Wrench

Built for Heavy-Duty Gripping Power

The SNTP IronJaw - Pipe Wrench delivers maximum gripping force with minimal effort. Forged from premium-grade steel and finished for corrosion resistance, IronJaw is ideal for site operations requiring reliable coupler tightening, pipe handling and fastening.

Key Benefits:

-

Strong jaw grip with anti-slip teeth and anti-slip hand grip

-

Heat-treated for enhanced strength and wear resistance

-

Ergonomic handle for better control and reduced fatigue

-

Suitable for steel reinforcement work, plumbing, and site utility needs

-

One universal size suitable for dia 12mm-50mm

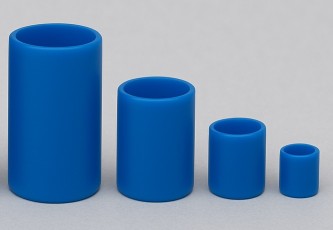

Rebar Thread Protection Cap (PVC / LD)

Essential Protection for Precision-Threaded Bars

SNTP's Rebar Thread Protection Caps are designed to safeguard the threaded ends of reinforcement bars during storage, handling, and transportation. Available in both PVC (Polyvinyl Chloride) and LD (Low-Density Polyethylene) materials, these caps ensure that the threads remain free from damage, corrosion, and debris prior to coupler installation.

Key Features & Benefits:

-

Prevents mechanical damage to threaded rebar ends

-

Shields threads from dust, moisture, and site contaminants

-

Enhances installation accuracy and coupler fitment

-

Easy to apply and remove without special tools

-

Available for all standard rebar sizes (12mm to 50mm)

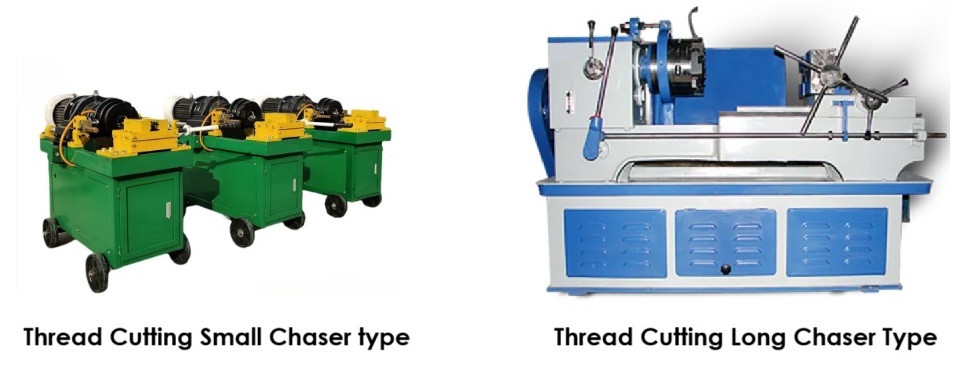

SNTP TMT Bar Threading Machine

Precision Threading for Stronger Bar-to-Bar Connections

The SNTP TMT Bar Threading Machine is a high-performance threading solution engineered for creating ISO metric threads on reinforcement bars (TMT) to facilitate mechanical splicing using couplers. Designed to deliver consistent thread quality and dimensional accuracy, this machine is ideal for both in-plant and on-site operations.

Key Features & Benefits:

-

Threading Range: Compatible with TMT bar diameters from 12mm to 50mm

-

Precision Threading: Achieves uniform ISO standard threads

-

Heavy-Duty Motor & Gearbox: Ensures stable and continuous operation under site conditions

-

Thread Length Adjustment: Customizable thread lengths based on coupler specifications

-

Operator-Friendly Design: Easy to operate and maintain, with quick-change die heads

-

High Production Rate: Ideal for bulk coupler installations in infrastructure, metro, tunnel, and high-rise projects

-

IS 16172:2023 Compatible: Fully compliant with Indian standard requirements for mechanical splicing

SNTP Rebar Upsetting / Cold Forging Press Machine

Enhanced Bar End Strength for Superior Threading

The SNTP Rebar Upsetting Machine is engineered to increase the cross-sectional area of rebar ends before threading, ensuring optimal strength and reliability in mechanical splicing. This hydraulic machine delivers consistent and high-precision upsetting—critical for coupler-based joints in infrastructure projects requiring full tensile performance.

Key Features & Benefits:

-

Increases bar-end diameter for better thread depth and grip

-

Suitable for bars from 16mm to 40mm (customizable up to 50mm)

-

Heavy-duty hydraulic system for continuous site or factory operation

-

Compatible with IS 16172:2023 compliant threading processes

-

Built for ease of mobility and low maintenance